"We need to invest today to ensure that we have the infrastructure, production capabilities, and workforce in place to meet future market demand and provide the best products to our customers worldwide.” 17 November 2022 In News With the majority of exterior construction complete, Pratt & Whitney’s new turbine airfoil production facility in Asheville, North Carolina, is expected to achieve initial operational capability in the second quarter of 2023.

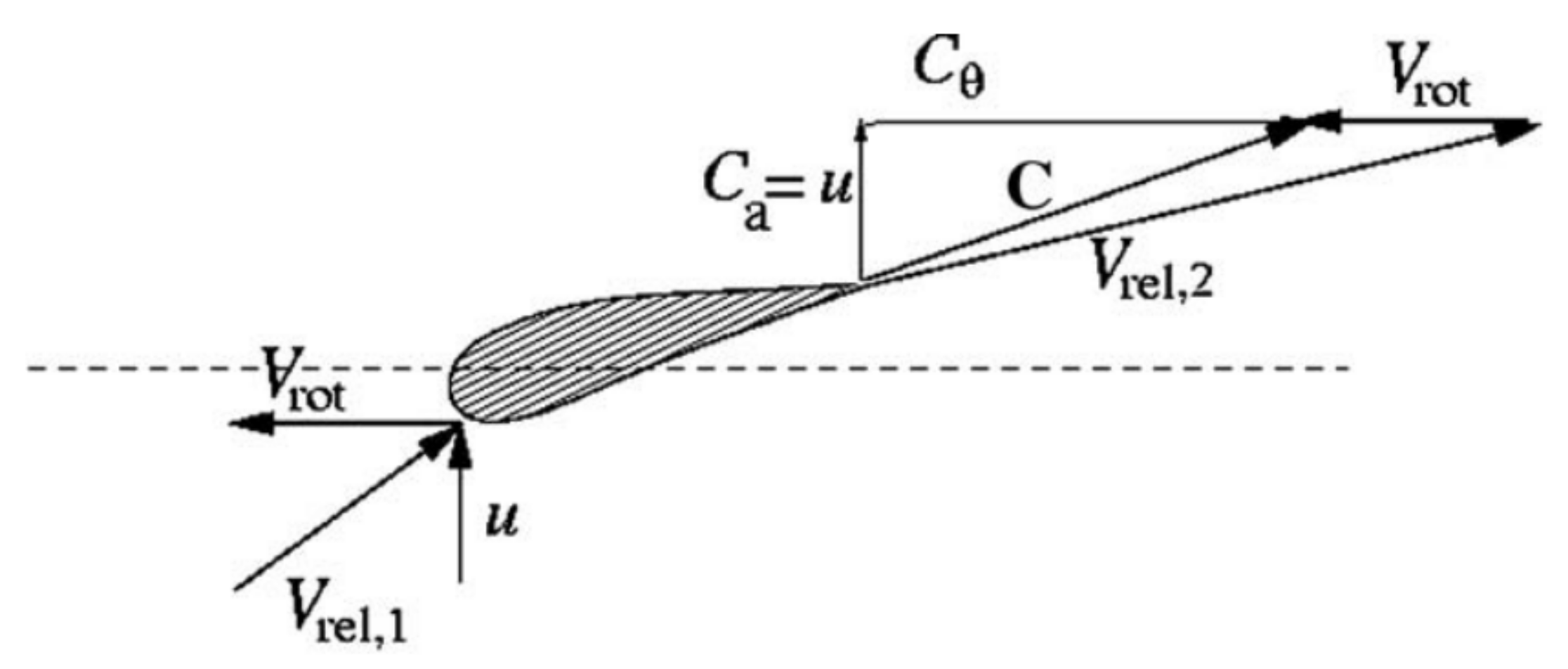

“Turbine airfoils are a critical component across our engine portfolio and demand will increase significantly as the market recovers over the next several years," according to P&W president Chris Calio. Investment casting is the preferred manufacturing process for airfoils because it can be used to produce specialty alloy parts with directionally solidified (DS) and single-crystal oriented structures, which are necessary for maintaining the thermal and mechanical endurance required for aircraft engine reliability. Pratt & Whitney designs, manufactures, and services turbofan engines for civilian and military aircraft and helicopters, along with auxiliary power units, a primary component of which are airfoils - the wing-shaped structures arranged in sequence in an engine to draw and direct air through the turbine, to accelerate airflow and generate lifting power. The manufacturer further noted that the new plant will adopt processes "exemplifying Industry 4.0 manufacturing principles and will complement existing turbine airfoil work that is done across Pratt & Whitney’s facilities." The plant also will include onsite machining, coating, and finishing capabilities for airfoils. "advanced casting foundry" for turbine airfoils. Pratt & Whitney is committing to invest at least $650 million through 2027 to build an investment-casting plant in Asheville, N.C., described as a 1 million sq.ft.

0 kommentar(er)

0 kommentar(er)